Pumping / Lifting Stations & Rising Mains

- Home

- Pumping / Lifting Stations & Rising Mains

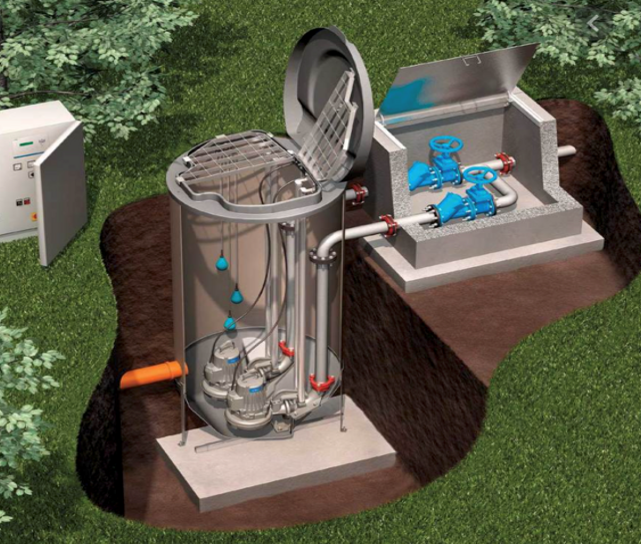

Sewerage Pumping /Lift Station

Pumping stations are either in-line for pumping the sewerage from a deeper sewer line to a shallow sewer line or for conveying to the wastewater treatment plant or an outfall. They are also designed where sewerage from development areas or new collection networks when is not able to be drained by gravity to existing sewerage infrastructure, or where development areas are too far from available sewerage infrastructure to be connected by gravity conduits.

Therefore, in the case of pumping sewer from a deep manhole to a shallow adjacent manhole, it is called lift station. In the other cases, to convey sewer to a far distance facility, it is categorized as pumping station. Although the technical criteria are similar, generally pumping stations required significant considerations such as the design and operation of force mains.

Preliminary Study

Design Flow, Min. & Max. sewer flow, Run-off estimation, etc.

Location and Configuration; Local topography, Size and type of the pumping station, Access considerations for O&M needs including operators’ health and safety issues, Visual impact, particularly the vent tube, odors, noise problems, etc., Vulnerability of the site to a natural and man-made disaster.

Design of levels; Suction level, discharge level and top or bottom alarm levels

Design of equipment

Designing the equipment installed in the sewerage pumping station including; gates, screens, grit removal systems, conveyors, odor removal system and piping.

Design of Pump

Types of pumps, types of Pumping station & number of Pumps; Due to the operation and maintenance costs, these parameters are considered one essential factor to design sewerage pumping stations. Proper type and number of pumps not only will provide a situation to operate effectively, but also save the energy consumption in any conditions and maintenance costs.

Design of Instruments

The design of instruments in the pump stations includes;

➣ alarm system,

➣ flow and pressure monitoring system,

➣ the control system for best performance during the operation.

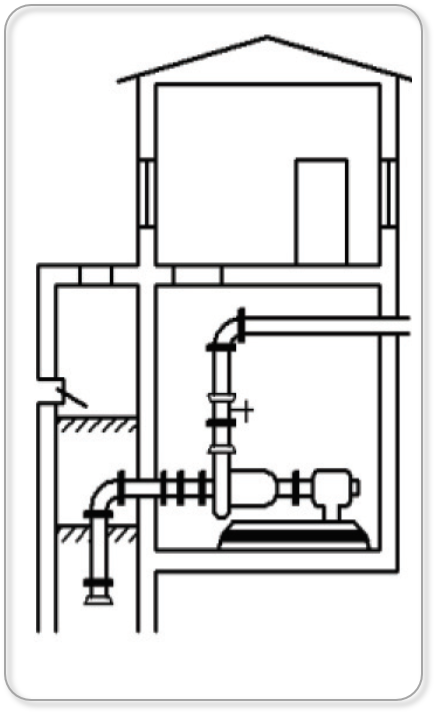

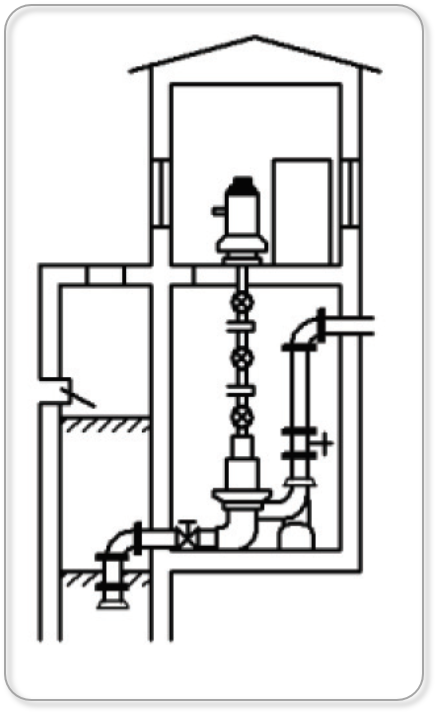

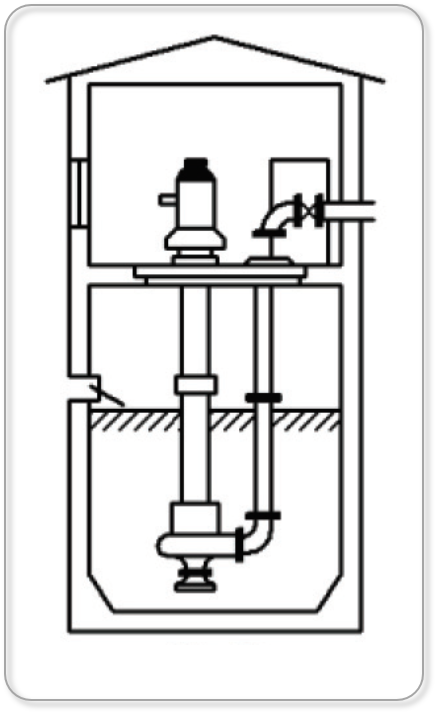

Main Types of Sewerage Pump Station

Design of Pump

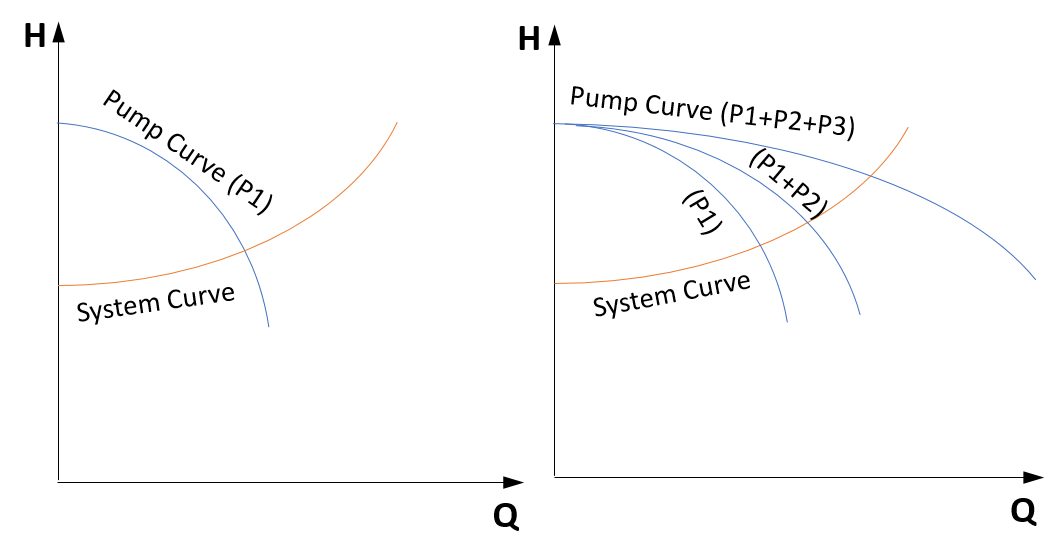

Pump Selection the size and the numbers are challenging and it should be designed properly to serve the best performance in any flow conditions and provide the required head to transfer the flow with energy saving consideration. In the following figures, the system performance curve and pump curves are illustrated.

Designing a pump station just with one pump in operation required more volume for suction pit to store and equalize the flow in dry flow or wet weather conditions. Therefore, the constructional cost is increased dramatically. Although it seems the operation of one pump is more simpler, the total cost in the lifetime, the maintenance costs, energy cost, etc. would not be less than other options.

Designing pump stations with multiple parallel pumps are more economic and practical in many aspects. For example, in case of minimum or average daily dry flow conditions, just one pump could be operated. In maximum flow, two pumps are in the service and in wet weather flow, three or more pumps may be considered to convey the flow. Therefore, due to less volume for suction chamber, the construction costs will be decreased and it provides a flexible situation for operation. On the other hand, increasing the number of pumps could be complicated for the operators and the more pumps, the more costs of operation and maintenance. Therefore, there is a technical challenge to balance the construction costs, operation and maintenance costs which could be overcome by an engineering concept. To conclude, the number of pumps is the main factor and it needs optimal design to consider all the aspects.

On the other hand, designing pump stations with multiple parallel pumps is more economical and practical in many aspects. In minimum or average daily dry flow conditions, just one pump could be operated. In maximum flow, two pumps are in the service and in wet weather flow, three or more pumps may be considered to convey the flow. Therefore, the construction costs will be decreased and it provides a flexible situation for operation. To conclude, the number of pumps is the main factor and it needs optimal design to consider all the aspects.